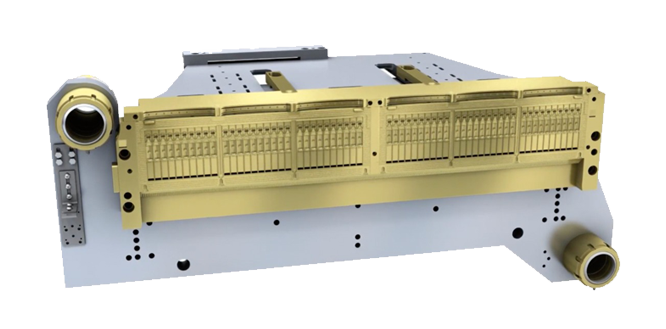

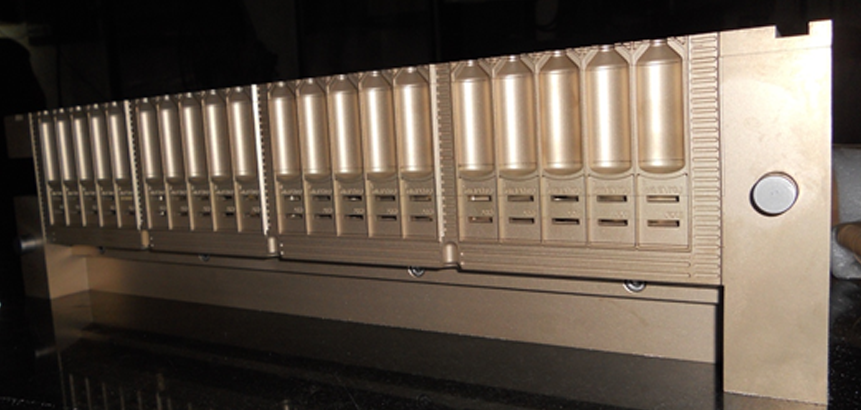

We Design

Friscohn, The British American Engineering Company, welcomes you to the world of Blow-Fill-Seal machines & tooling.

Friscohn has expertise in high end Blow-Fill-Seal Technology and serving the niche since 2005. The global Pharmaceutical Industry has appreciated our quality and support, over years. We are the only Private Label Blow-Fill-Seal tooling design & manufacturing Company for the top international Brands manufacturing the Blow-Fill-Seal machines as well as the prestigious Blow-Fill-Seal operators, worldwide.